Laser Cutting

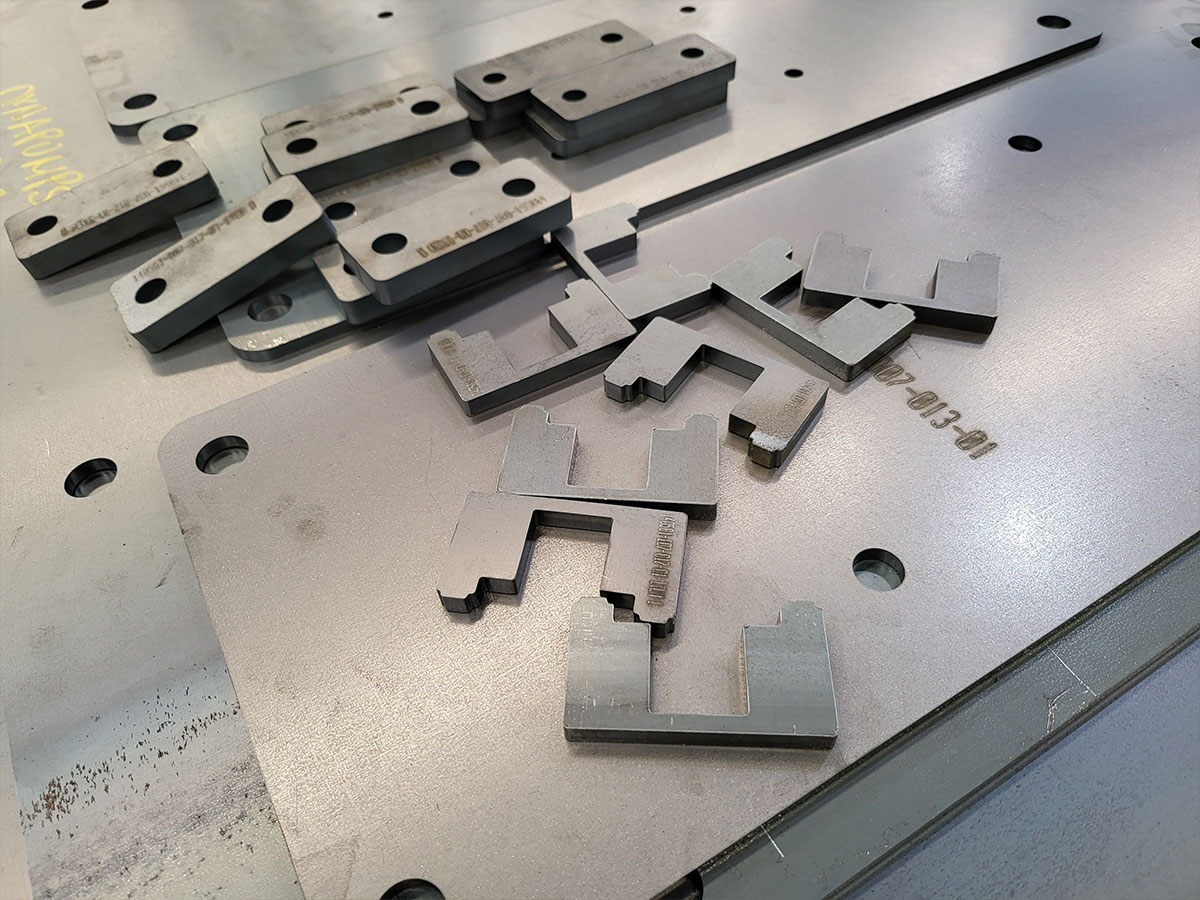

Precision Cutting for Complex Designs

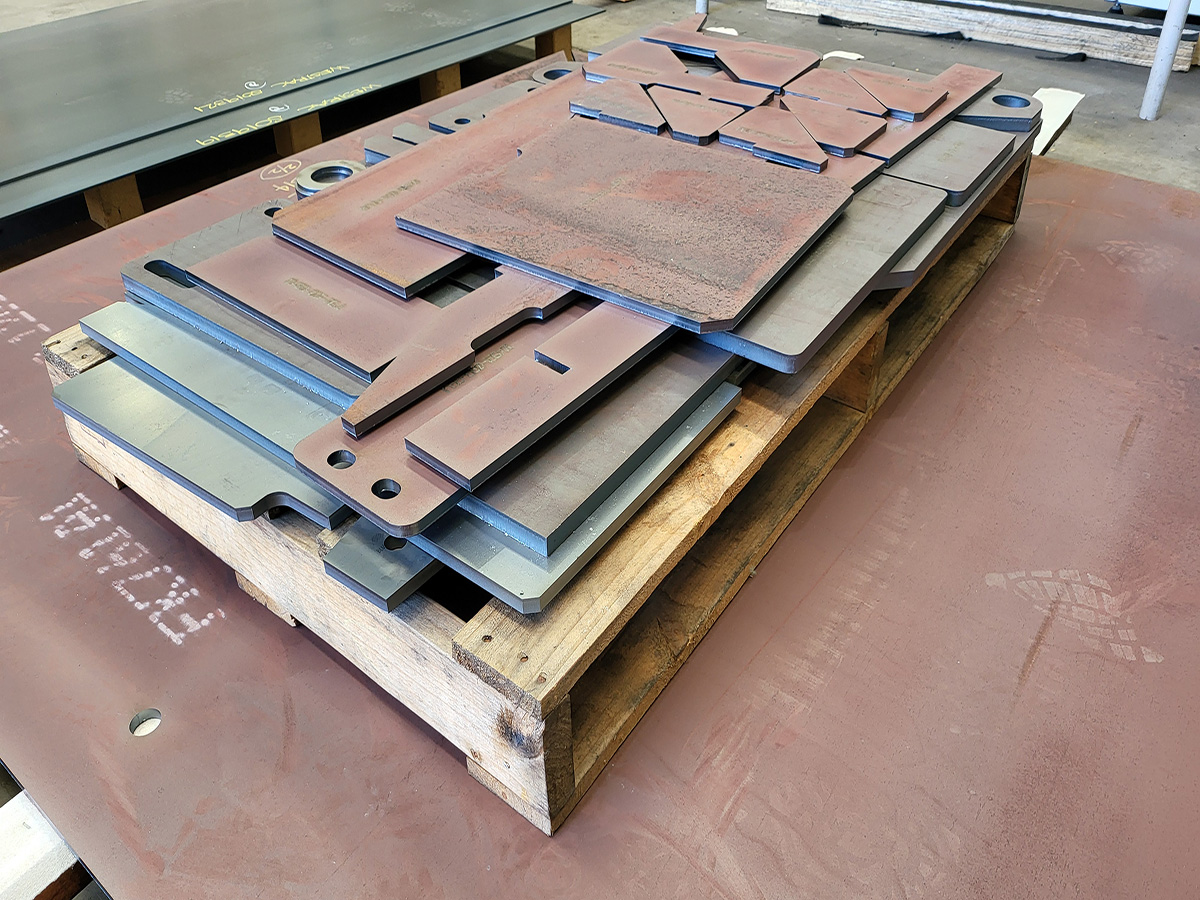

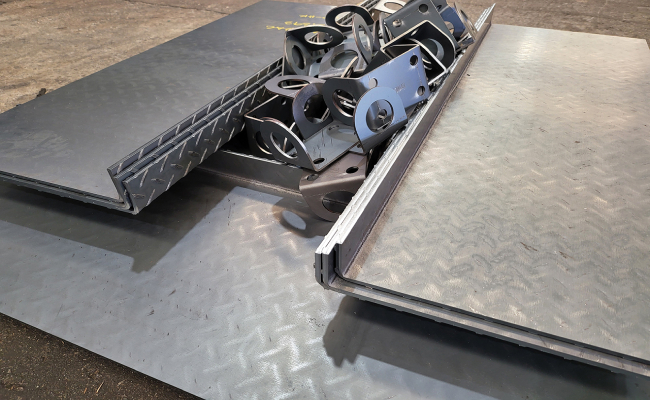

At Di Candilo Steel City, our advanced laser cutting services offer our customers unmatched precision and versatility, enabling us to handle even the most intricate designs with ease. Whether you require simple cuts or complex shapes, our laser cutting capabilities deliver high-quality results for a wide range of materials and applications.

What is Laser Cutting?

We use a focused laser beam to melt, vaporise, or burn through metal. It allows for clean and accurate cuts with minimal distortion.

Our Bayswater facility houses the latest in fiber and CO2 precision laser cutting technology.

Both of these processes are ideal for projects requiring intricate details, sharp edges, and clean finishes. It’s perfect for a variety of metals, such as stainless, aluminium, galvanised and carbon steels.

Fiber Laser Cutter Services

A fibre laser generates a high-power light beam inside an optical fibre, which is tightly focused onto the metal surface.

The focused beam heats the metal until it melts or vaporises, while a pressurised gas removes the molten material, producing a clean and precise cut.

This method is especially effective for cutting thin to thick metals (0.55mm-25mm) like stainless steel, mild steel, and aluminium.

CO2 Laser Cutter Services

A CO₂ laser uses electrically excited carbon dioxide gas to produce a high-power infrared beam, which is focused onto the steel and heats it until it melts.

A pressurized assist gas then blows the molten steel out of the cut, allowing precise and continuous cutting.

The beam operates in much the same way as the fiber laser cutter. It is well suited for cutting non-reflective metals like mild and stainless steel, and excels in cutting a range of thicknesses.

Some Commonly Asked Questions

We laser cut a wide range of steel objects, including machinery components, trailers, conveyors, mining equipment parts, and custom artistic panels such as gates, fences, signage, and tags.

The list of steel objects we can laser cut is (almost) endless, so get in touch with our team if you have a specific requirement.

Yes and no. While the fibre and CO2 laser cutting machines are powerful and can produce intricate shapes and designs, they run optimally within specific parameters. We can guide you through what is and isn’t possible to ensure the quality and utility of your steel are not compromised.

Depending on your needs, our sales consultant can assist and arrange part or all of this for you. We work with trusted partners who are experts in their field and will ensure everything is handled efficiently and to a high standard.

Once we have completed laser cutting your steel, you can collect it from our premises in Bayswater, just 13km from Perth City.

Related Services

Custom Cutting Solutions

Our expert team in Perth is ready to deliver custom solutions that meet your exact specifications. Contact us now to discuss your needs and receive a personalized quote.